Procurement

- •Track supplier performance

- •Identify cost-saving opportunities

- •Measure real ROI

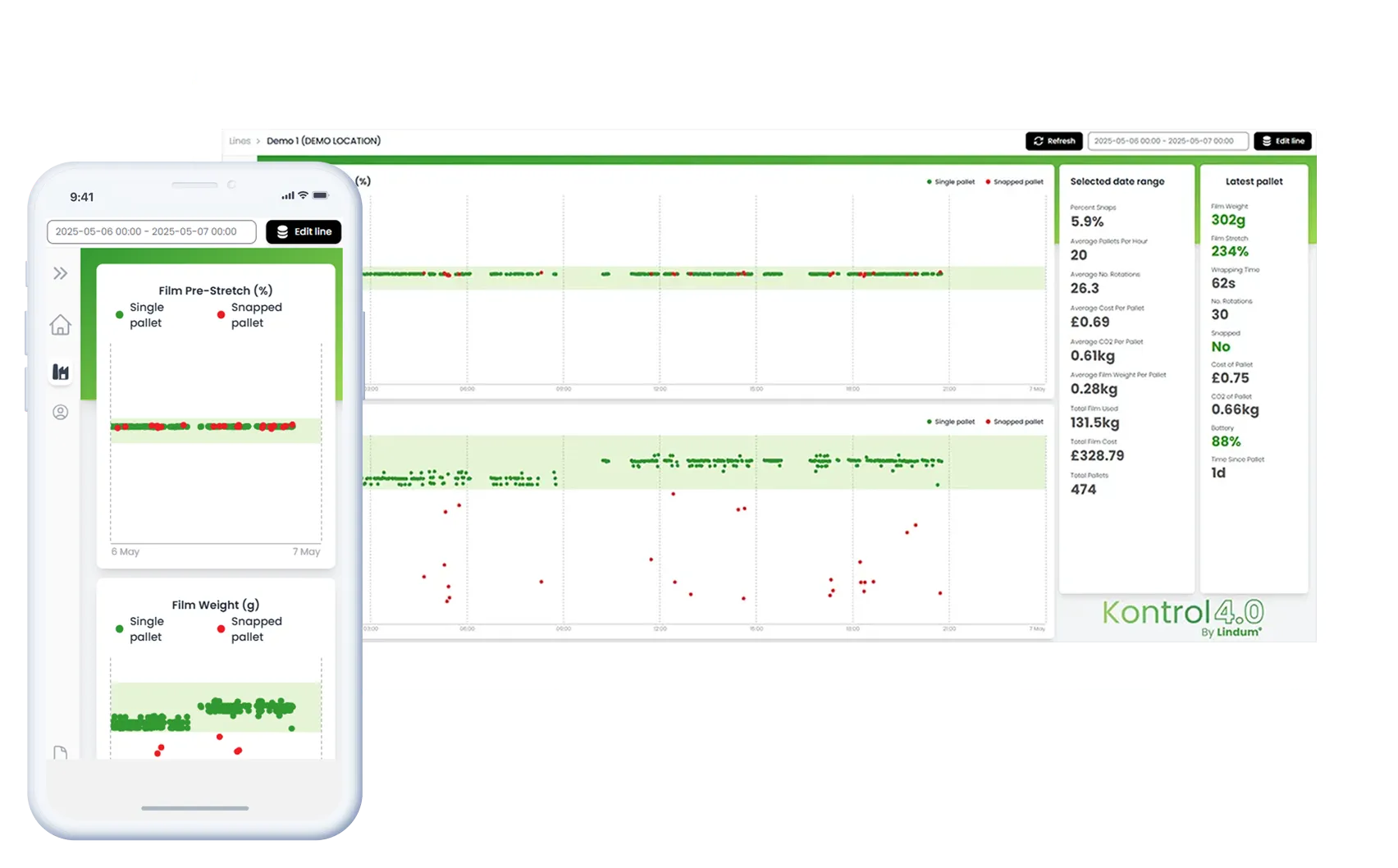

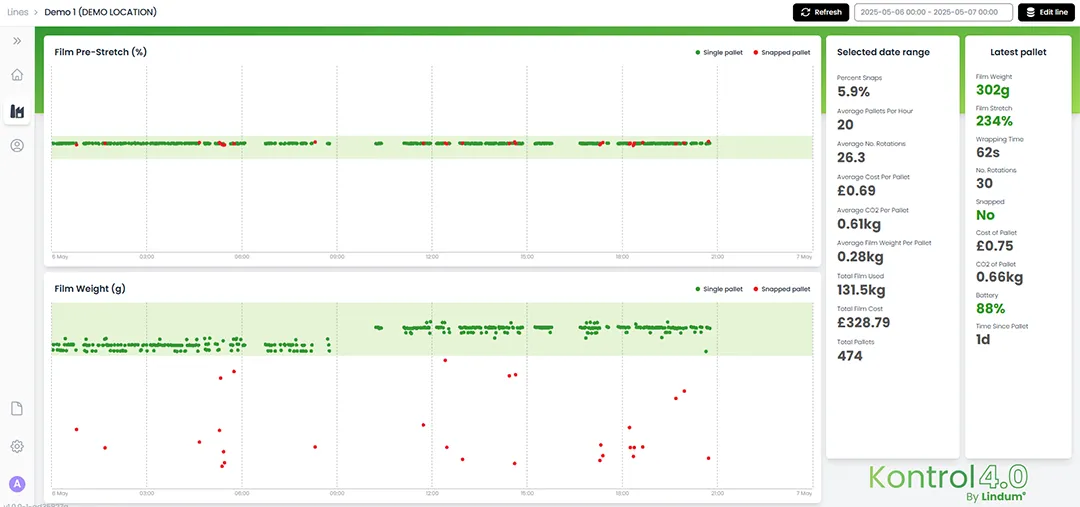

Kontrol 4.0 gives you full visibility over every pallet you wrap - so you can cut waste, reduce costs and keep standards high, every time.

Whether your aim is to improve pallet stability or reduce material usage, Kontrol 4.0 helps you to set your pallet wrapping standard and ensure it is maintained over time.

Get in touch.